Reliable Solutions: Undercarriage Parts for Heavy Equipment

Quality undercarriage components play a significant duty in making sure the smooth operation and long life of hefty machinery. In this conversation, we will discover the significance of spending in superior undercarriage components, usual wear challenges dealt with by heavy equipment operators, the advantages of timely substitutes, standards for choosing reliable distributors, and crucial upkeep pointers to expand the life expectancy of undercarriage elements.

Significance of Top Quality Undercarriage Parts

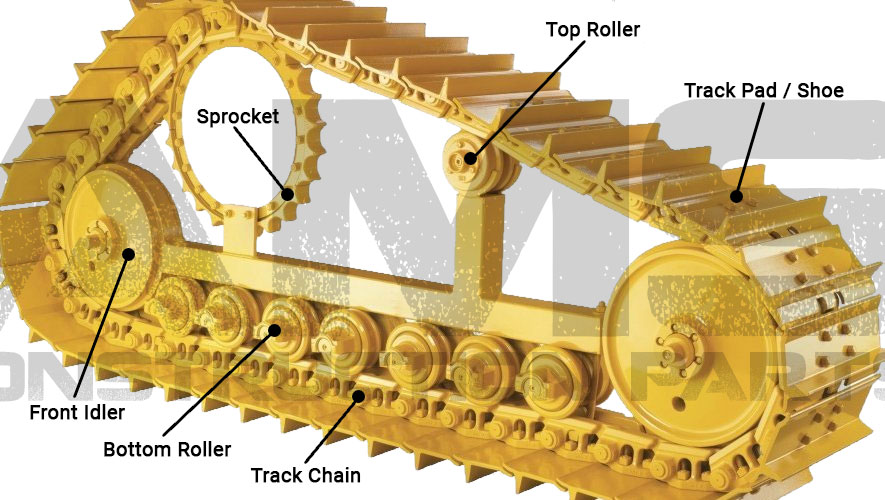

Quality undercarriage components are essential parts in making certain the longevity and efficiency of hefty equipment. The undercarriage of devices such as excavators, excavators, and track loaders plays a vital role in sustaining the machine's weight, supplying stability on various terrains, and taking in the impact of unequal surface areas. By purchasing top quality undercarriage components, operators can significantly expand the lifespan of their machinery and reduce the risk of unanticipated breakdowns.

One key advantage of using top quality undercarriage parts is the improvement of total maker performance. Durable tracks, idlers, rollers, and sprockets decrease rubbing and make sure smoother movement, ultimately resulting in increased productivity and effectiveness on task sites. Furthermore, dependable undercarriage components decrease downtime for maintenance and repair work, permitting operators to optimize their operational hours and project deadlines.

Usual Undercarriage Put On Concerns

Benefits of Timely Substitute

One key advantage of prompt undercarriage component substitute is raised machine uptime. By changing worn parts prior to they stop working, the threat of unexpected break downs is decreased, minimizing downtime for repair work and upkeep. This aggressive method not only keeps the hefty equipment operational but also avoids prospective damage to various other elements that can result from a failing undercarriage.

In addition, changing undercarriage parts without delay can enhance have a peek at this site total efficiency. Spending in prompt undercarriage component substitute is an aggressive strategy that pays off in terms of improved effectiveness and reduced functional costs.

Picking the Right Undercarriage Supplier

Choosing the proper undercarriage supplier is a vital decision that dramatically influences the efficiency and upkeep of heavy machinery. When selecting a distributor for undercarriage parts, a number of factors have to be taken into consideration to make certain optimal effectiveness and cost-effectiveness. A vendor that supplies a wide choice of undercarriage components for various heavy equipment brand names and versions can be useful as it gives a lot more choices to fulfill particular demands.

Stabilizing cost-effectiveness, integrity, and quality is crucial when selecting the appropriate undercarriage distributor for heavy equipment. By thoroughly reviewing these elements, you can pick a provider that meets your needs and adds to the efficient performance and maintenance of your hefty equipment.

Maintenance Tips for Extended Life Expectancy

To make sure a prolonged lifespan for hefty machinery undercarriage parts, implementing an aggressive maintenance regimen is necessary. Investing in top quality undercarriage parts from reliable distributors is equally vital for making sure longevity. By complying with these upkeep tips carefully, heavy equipment owners can maximize the performance and sturdiness of their undercarriage components, ultimately reducing downtime and operational costs.

Final Thought

Finally, quality undercarriage parts useful site are important for the effective procedure of hefty machinery. Timely substitute of worn parts can protect against costly downtime and maintain ideal efficiency. Choosing a dependable vendor and adhering to correct upkeep practices are essential to making certain the extended lifespan of undercarriage elements. By addressing common wear issues and investing in top notch parts, hefty equipment drivers can make the most of efficiency and decrease maintenance prices.

Too much wear and tear on undercarriage components of heavy equipment can lead to considerable functional difficulties and raised maintenance prices. Normal assessments, proper upkeep, and prompt replacements of used undercarriage parts are necessary to alleviate these usual wear problems and guarantee the optimal functioning of heavy equipment.

A provider that offers a large selection of undercarriage parts for numerous heavy equipment brands and designs can be advantageous as it offers extra options to satisfy certain requirements.

By adhering to these maintenance suggestions carefully, hefty machinery owners can enhance the performance and resilience of their undercarriage components, eventually minimizing downtime and functional expenses.